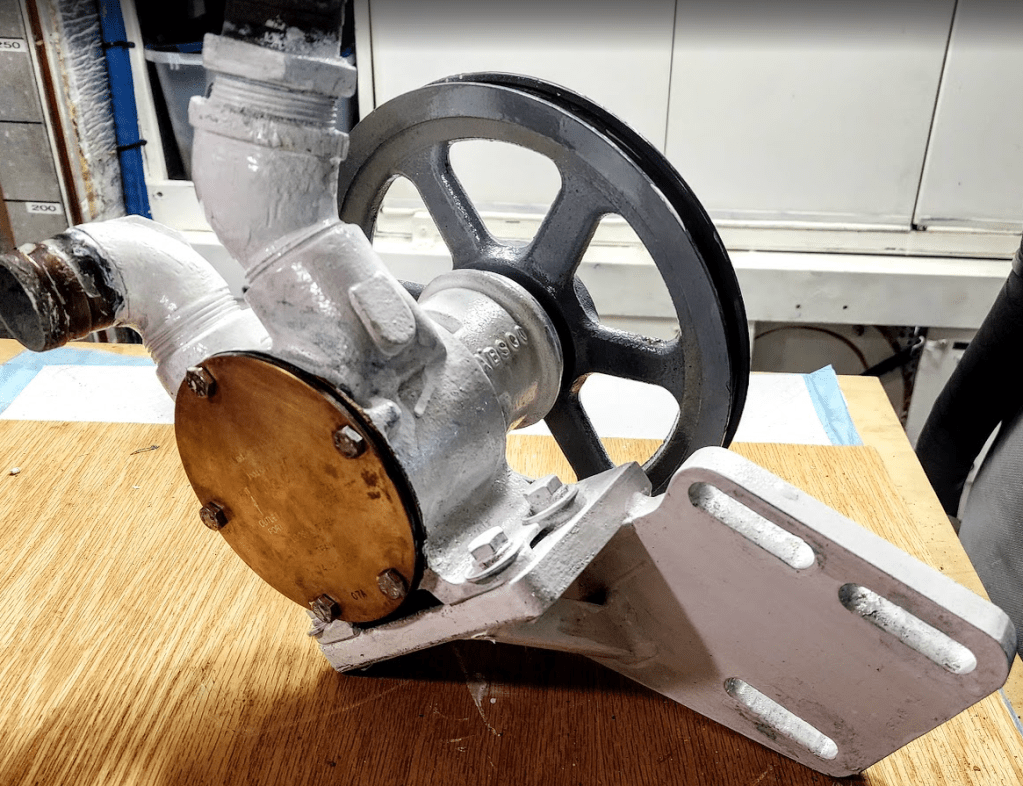

Part of the fall maintenance program includes changing the oil on both engines and gen sets if warranted. The oil change process is straight forward. The hardest part is unscrewing the old filters. Mischief managed. New oil and filters are in place. That left the impellers. I’d done both gen sets already which left the larger, harder to access 3208 Cat water pumps.

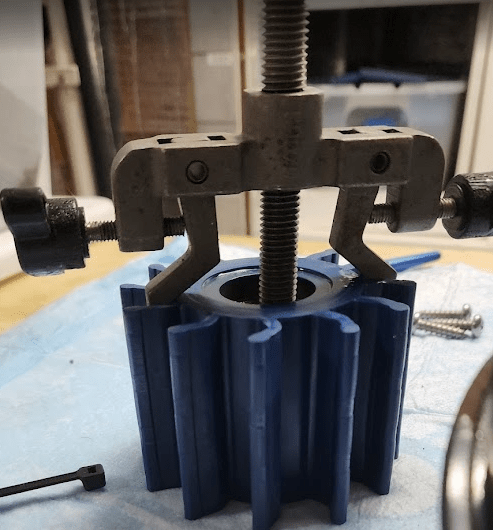

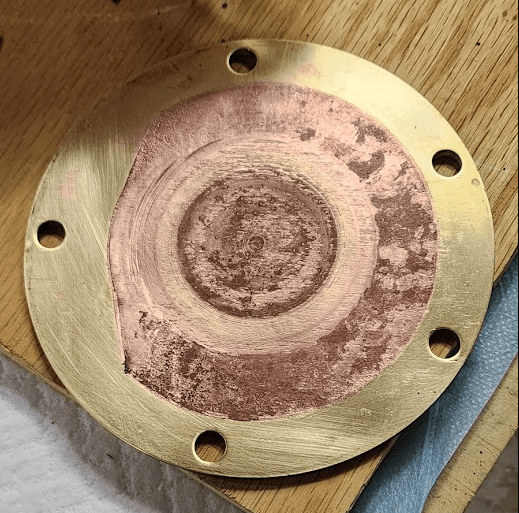

Tools of the trade:

Messing around with George (stbd engine) took about 4 hours including painting and reinstallation. Fred (port engine) was easier and took only 3 hours or so… only because I could utilize the tricks I learned wrestling George to the mat. And now I have this nice blog to refer to when I perform this magic again in 400 or so hours of engine run time.