It is possible for ones disposition, working on boats in exotic places, to devolve into an impassioned pantomime of Sisyphus… pushing a large boulder up an interminable hill. I do know from observing Les’s strained countenance when helping me to solve a recalcitrant engine room issue, that I am nearing the moment when she is about to vacate the engine room and leave me to contemplate my unreasonable demeanor. I’m not sure if it is the expletives or the whimpering that drives her away. Most likely it’s the combination of the two. It does seem that every time I develop confidence having mastered a certain tool, motor, pump, or electronic device… the Sisphusian boulder slips from my sweaty and oil soaked hands and rolls right back down to where I first started pushing it around. There is a silver lining: I find out at that moment how much I have yet to learn about boats, and my 45 plus year relationship with a very patient partner.

The incident that started the most recent series of equipment malfunctions occurred when we were crossing the Strait of Georgia on our way from Nanaimo on Vancouver Island, to Pender Harbor on the mainland of British Colombia. We started hearing this odd harmonic. It wasn’t either of the engines, the gen set or an alarm. We finally tracked it down to the NAIAD system and shut it down. It was a fairly quiet crossing so no harm… just a bilge fouled with oil from a ruptured hydraulic line. We shut down the system, and pinned the fins which stops them from flopping about. Pinning the fins in place also stops more oil from leaking down into the bilge. Cleanup warranted. We were headed to Princess Louisa Inlet and it wouldn’t do to blop dirty, oily bilge water into those pristine waters.

On the morning of our 3rd day in Princess Luisa Inlet, we suffered a crane failure. We lifted Les’s kayak into its rack on the flybridge using the crane, and had my kayak up in the air hovering over the flybridge… and the crane just stopped. Well, it didn’t just stop. First it began emitting an odd gurgling noise. Then it stopped. It wouldn’t go up or down. My kayak was marooned 6 feet in the air, an 18 foot long, 60 pound grandfather clock pendulum just waiting for a boat wake to make it wobble about and wreak havoc. We tied it off so it couldn’t swing, and figured out a way to get it down into its rack. Thank dog it wasn’t our heavy dinghy that was stuck up in the air. That would have been much harder and more dangerous to get down… although we have tools on board that would have made that possible. One must be prepared…

Several days later… after crossing the Strait of Georgia, passing through Dodd Narrows, spending the night in Sibell Bay near Ladysmith, pushing through Sansum Narrows, and skirting the Southern shores of Saltspring Island… we arrived in Sidney and got a slip at the Van Isle Marina. We had Delta Marine replace the blown NAIAD hydraulic hose and two hydraulic hoses in the crane. Both of the offending machines were back to work. Vacation over. Mischief managed.

We spent the next 3 days at Tod Inlet just idling about, performing the hard work of cruising about in a boat. Hiking, paddling, reading, cooking, eating, napping, sleeping… dreaming. On day three… the little gen set (9KW) wouldn’t start. (what is it about day 3?) Oh, it would start all right, but only run for about 8 seconds and stop. It was clear that no water was moving through the cooling system and the appropriate sender noted the condition and stopped the engine from overheating. On top of that, it was raining outside. It had been raining all night and was going to continue to do so. That of course, was not the generators fault, but, three is a charm as they say: Crane, NAIAD stabilizers and now a generator. So… as that can be contrived into the realm of omen… we decided that a change of scenery was warranted. The Strait of Juan de Fuca was wind and swell free for the most part, so we raised anchor and made our way back to the States. After struggling a bit to achieve our customs entry through Roche Harbor on San Juan Island (our US Customs reentry CBP Roam application failed us…) about 8 hours later we were back in Port Ludlow.

The next morning found me ensconced in the engine room surrounded by my favorite dismantling tools:

I removed the generators water pump, took it apart and found:

After finding the water pump impeller in shreds… I then had to get to the heat exchanger and retrieve all the broken vanes that were sure to be there blocking future water flow. To do that I had to remove the oil filter. That’s right. Some silly engineer type put that right in the way. So: empty the oil from the engine, remove the filter, remove the end cap of the heat exchanger and remove the bits and bots that were not supposed to be there:

I extracted the offending miscreants with tweezers and the odd pair of forceps. I have several pair and they come in very handy for such tasks. Upon closer examination, I also found that there were cracks in the end cap of the heat exchanger. So… I took off the cap on the other end and found that it was cracked as well… I replaced the gaskets, o-rings and end caps with all new OEM parts. And while moving a wiring harness out of the way I found a cut wire in the bundle of wires leading to some of the senders. I repaired that. I also noticed that there were a few bald spots on the belt. I replaced it. That done, I buckled up the heat exchanger, screwed on a new oil filter, filled the engine with oil, and bolted the water pump back in place with its newly installed run dry impeller. After hooking all the hoses back up, turning the battery switch on, and pushing the start button: She ran beautifully. I loaded her up by turning on space heaters and a few other electron magnets. She moved electrons around with reckless abandon. All is well with the little generator (Ginny by the way, is her name…)

This was, as the title suggests, a week of reparations. Next up: our 23 KW genset, “Everything’s gotta have a name doan it”, “Hagrid”. I removed the water pump wear plate cover and inspected the run dry impeller. Perfect shape, with only 67 hours of run time on the meter since my last notation. I then checked the oil. Perfect honey colored Amsoil good for 500 hours of run time. OK for now. I then endeavored to replace the heat exchanger zinc… and it broke off. “Crap”! (and other more devious expletives burst from my lips). Les wasn’t there, so the ploy of wimpering just wasn’t necessary. Who would I be impressing? So… I removed the heat exchanger end cap as a reprise and in honor of examining and replacing Ginny’s end caps. Here’s what I found:

I installed a new zinc, reinstalled the end cap (noting that I needed to get a few spare gaskets) buckled everything back up and started it. Hagrid was happy.

Next up: Cat 3208 impeller replacement and oil change. The impeller change out is not as easy as on the gen sets. First… the water pumps are much larger, heavier and need to be removed from the engine to replace the impeller… Now if the gull dern engineers had allowed just one more inch of room for the pumps, they would not need to be removed from the engine. Well… they actually don’t. But, then again… it’s not all that hard to do. Les was very helpful and I didn’t devolve. The impellers were fine, but I replaced them with new run dry impellers. We don’t want impeller shards rampaging through the intercoolers and heat exchangers now do we? The engines now have new filters and oil. I didn’t change the transmission oil and filters. They still have some time to go…

So there we have it. Another week of fixing Great Northern in exotic places. Now all we need are groceries, stores, fuel and a good weather window to cross the Strait and get on with our next Hudsons Bay Company test in the San Juans. If all is well… it’s back to Canada, the Gulf Islands and parts North…

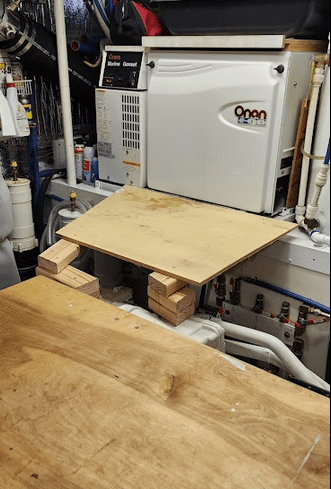

Addendum: To assist engine and other work, I’ve constructed work benches over each engine. They lift up out of the way while traveling to maximize engine cooling:

Maybe some day, those benches will be painted… Let it not be said that performing engine work on a working trawler / home, need be uncomfortable or ergonomically displeasing…

…Blair

The work benches look gre

LikeLike

Can you spell… man-cave. Great to see you are watching. Boat’s in great mechanical shape for the most part. Port tranny is suspect going into gear so smoothly compared to stbd, but so far it still goes easily into gear… and stays there. Will have autopilot motor rebuilt this winter.

LikeLike

I’m almost 78. The more I think we I replaced impellers.

LikeLike

They are fond of shredding blades, eh? I’ve converted all to the run dry type. Except I couldn’t find one for the little genset. Paid a price for rhat, I did. Now I haven’t spares for all. The synthetic “rubber” doesnt shear as readily as you know. Pricey though…

LikeLike

I mean Vaseline.

Sent from my iPhone

<

div dir=”ltr”>

<

blockquote type=”cite”>

LikeLike

Lost me there dear sir…

LikeLike

Always something.

Sent from my iPad

<

div dir=”ltr”>

<

blockquote type=”cite”>

LikeLike

Yup… it’s a boat, eh?

LikeLike

Now that’s a lot of work. Stuff just breaks on a boat. Looks like if

you don’t do it yourself it may not be done properly, too. Makes the

piddly stuff I do around the house look piddly. Still – travel! I

really like your auxiliary workbench areas. You can never have enough

workbenches.

Jack

LikeLike

Not so much breaks, but it all has to be maintained to keep it from breaking. Changing out impellers is not tecnically difficult, but it has to be done. Changing zincs, impellers, oil, filters etc.does take some time. And there’s lots of oil. 18 gallons all told… engines, trannys, gensets, NAIADS. Its a once every 1.5 year deal. Now we should be ready to get out there some more…

LikeLike

Impressive how self reliant and confident you guys are!

LikeLike