Potentially… it was past time. One never quite knows for sure, does one? When does an ominous, lurking probability become an irreversible deed? I presume that’s when it gives up the ghost, breaks apart, and in this case, stops impelling. That’s a finality of sorts. A bustication as it were. That being stated, a foundational question might be asked: How long should an impeller in a marine diesel engine be expected to perform before it breaks? Should an impeller’s useful life be measured by hours of use… or is it better to think of it’s replacement in terms of a more generalized approximation: a boating season?

There are adages… based on the basic forgetfulness of the common boater, that pertain to this. Certain sage like creatures that lurk about the docks claim to have inner knowledge and a fair amount of certainty hanging about them. Stage presence. Speak with a clear and authoritative voice. Wear a convincing countenance. Mostly, that’s all it is. Sometimes they do know the answer, but again, it might be more of an approximation… a generalization… Like getting inferences about how to best lay down varnish…

Most engineers know all about this sort of thing. Likely considerations: Durability of different polymers, flexion intervals, stretch fatigue, pressure gradients, failure mode analysis, and finally… appropriate interval replacement. Hourly makes sense when viewed through a mechanistic lens now, doesn’t it? It’s got that feel of scientific backing, data points to consider. It has that all going for it…

But… relying upon seasonality reasoning would seem to simplify the whole decision making process. It does have a certain pleasant ring to it, a memory trope to make sure the deed gets done before its too late and more drastic measures must be taken.

I’m talking impellers here people! The care and nurturing of water pump Impellers! Important little rubber gadgets they are… Driven by belts and gears. Fit inside pump housings they do. Their little fins frenetically twirling around with reckless abandon, like miniature squeegees sweeping water from the innie side of the sea water intake, to the outie site of the pump housing. So what does that do? The lowly water pump spreads cooling substrate (sea water) throughout the diesel marine engine where needed. Mechanical marvels at that, eh? Can’t have a Chernobylesque engine meltdown now, can we? Gotta keep her cool mate.

Combustion of fuel is for the most part, a hot experience. That may sound simplistic to the mechanically inclined, or those who contemplate thermodynamics with understanding as if it were a first language. But for the rest of us mortal souls… how an marine engine converts fuel to forward propulsion is pure unadulterated magic. Science in action. Whirring parts. Rudimentary dear Watson… but what in fact, really contains the explosions that occur during combustion? Heavy metal, baby… heavy metal. If you are truly interested… follow the link to learn how a diesel engine works: https://blog.diamondracing.net/how-does-a-diesel-engine-work or not.

And… when diesel explodes in a compressed cylinder, in symbiotic entrainment with all the other pistons, fuel pumps, injectors, cams, etc. It is a truly amazing feat of design, metallurgy, and… heat production. Well now… to be more precise… diesel doesn’t really explode like gasoline explodes… it’s more of a slow burn made more dynamic because it’s under intense pressure. Bottom line: aerosolized diesel heated up by intense pressure, 23-25 times atmospheric pressure, makes the molecules frenetically bump into each other and try to escape. Wouldn’t you? Get me outta here! Well the only escape is to move the piston out… ahhh they must feel the relief. Out the exhaust valve, exhaust manifold, cooling elbow where more cool water is sprayed on their hot little aerosolized heads to cool them down. Out the exhaust and back out into the atmosphere to play with all the other aerosolized hydrocarbons already there. Kumbaya all around. Anyway, all the metal around the piston chambers gets hot when a diesel engine is doing it’s thing. The water pump and it’s impeller pump cool sea water around the engine to keep it’s cool. Enough of that I say! Digression… let go of my train of thought!

Back to my impellers. They’d been in there a while. 450 hours or thereabouts. Ahhhhh! Some might scream in mortal despair and fear. What a lunatic you must be! They are merely bits of neoprene or rubber. Well, in my case they are a specialized silicone based supernatural amalgamation of scientific genius. How many flexions can they possibly endure before they fly apart? Many it seems…

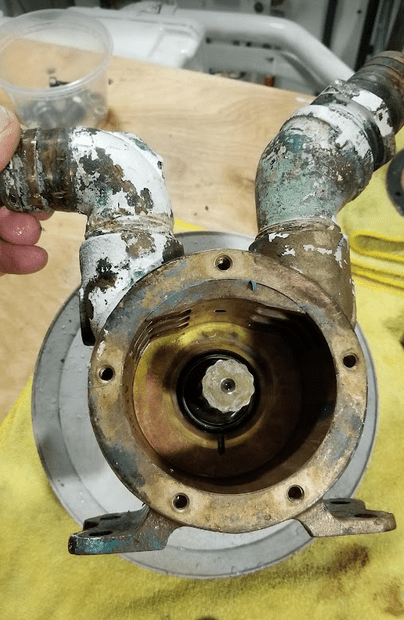

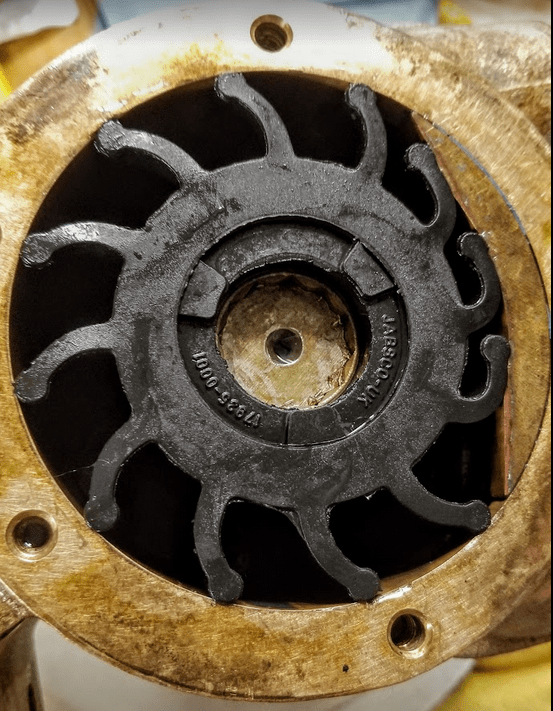

Lets see… 450 hours of operation. Lets just say… that I run the boat at 1500 RPMs. That’s rotations per minute thank you. So… let’s think about that for a moment. Every minute, the crankshaft spins 1500 times or thereabouts. The water pump is driven (I believe) off of the crankshaft. 1 rotation of the crankshaft means… x rotations of the water pump. Since I don’t know, and it doesn’t really matter for my point to be made… let’s just say the pump rotates at 1500 RPM. So… in 450 hours since being placed in the pump, the little impelling niffer has rotated 40,500,000 times (450*60*1500). And… here is what one of them looks like after such abuse:

Corrosion on the spline: What you can barely see, and what I can’t take a better picture of with my cell phone… is that the 12 pointed spline that is enshrouded with metal to plastic co-polymer magic fins… is just fine. The impeller blades have memorized their most likely rotational position… kinda like the Monterrey pines you might see on Carmel Drive… or out at Westport or Tatoosh Island. Where the wind blows, the pines lean. A simplistic, mechanical marvel it is for sure…

Anyway, there does appear that some degradation of the blades has occurred. The whitish spots might indicate some degradation. Obviously, the outer end of each curve has been elongated and the inner curve compressed. So I’m thinking… that the increased pressure on the inside of the blade has squeezed something out of the siliconized, plasticated matrix leading to a less-blue color. Yeah I know… who cares, really.

The most important data point to note is that all blades are clearly intact. If they were to break off… well… that is bad. Think of a blood clot breaking loose from a lower leg vein and making it’s way to the lungs and heart. Bad. Malas hierbos! Same thing could be said for an impeller blade breaking off and the bits going where they shouldn’t and blocking an important mechanism… like the one meant to cool the piston area. Malas hierbos!

Either way, the creature in question with the compromised coronary artery circulation just might topple over. Dramatically so. The poorly beating heart case goes via paramedics to higher care… As for the boat with the compromised cooling system… If the engine is not shut down in time it goes Chernobyl / Three Island. The pistons stop, the propellers stop propelling. The boat stops. That can be bad depending on how many engines in the boat, the weather, the location… like being upriver of a dam… or just north of a southerly current that is running at 10 knots with whirlpools and rocks and… other miasmas just waiting to ensnare an unfortunate boat and boater. Best to change out the impellers before that sort of thing starts to rule the outcome of the day and possibly the thereafter, eh? Then that frees up some brain cage space to consider other worries that lazily migrate out of their subconscious lair and make their presence known for conscious consideration. It happens. Usually late at night. Boats in general can be quite demanding caretakers…

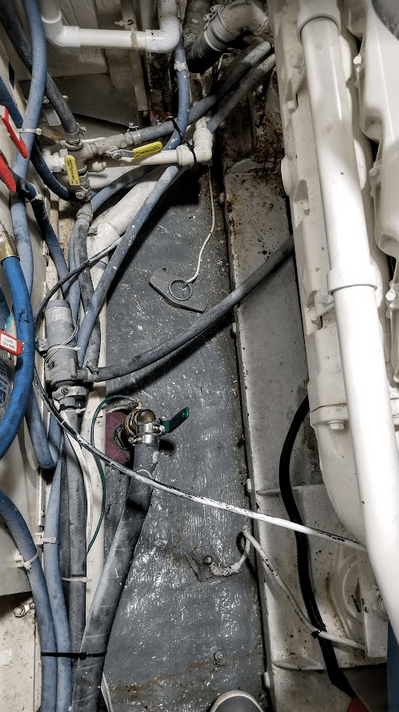

As I’ve said before… enough of all that inane prelude! Besides putting a note in my engine log to change out the impellers every 250 hours, a boating season in our case, so both theories are covered, the remainder of this post deals with an explanation of what steps I had to consider, and a bit of the process to change out the port sided impeller of my Caterpillar 375 HP turbo diesel engine.

First a look at some of the tools needed:

- THE STEPS: (skip this part if it’s kinda IDGAS for you.)

- shut off the the through hull that feeds Fred’s water pump. Yes our port diesel engine has a name. The Starboard engine is George. Best to name them just in case they have feelings…

- start Fred and run him for about 60 seconds. That get’s rid of most of the salt water that he is harboring

- Put on engine battle garb. Cloths you don’t mind throwing away, mechanics gloves, kevlar fore-arm guards, beanie to protect cranium from bolts and sharp stuff, headlamp. And then:

- remove the belt that runs the water pump

- remove the hose from Freds strainer to the water pump

- remove the hose that feeds the engine from the water pump

- remove the 4 bolts holding on the water pump

- remove said pump to the bespoke workbench hovering above the engine, for processing, cleanup, impeller replacement etc.

- No reason to go into putting the pump back in, but it was arduous. I’m thinking that modern diesels have better access to their impellers. Somehow I doubt it…

I used to dread removing old, hardened hoses from metal fittings. Radiator hoses were the worst. The sharp hose hooks are used to insert between the hose and fitting and makes them far easier to remove. There are many hoses on diesel engines, and I had to remove two of them to create space to work, and remove the pump from Fred’s clutches. There seemed to be some reluctance on his part, but… I am tenacious if nothing else.

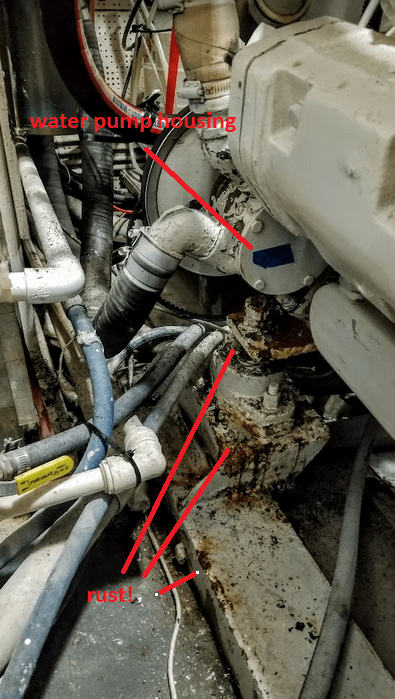

I scraped and painted the rusty parts of the engine mount, mount rail and waited for that to dry. Admiral Marine in Port Townsend supplied new hose for the water intake hose, which try as we might it would not fit the exit fitting from the Groco strainer, but did fit the fitting on the pump… Hmmm… let’s see… Groco strainer sourced through Maryland, water pump in the UK and the new hose from Italy. Go figure. Got it to fit, but I’m not a happy Captain. Changing it out has been added to the list of things to figure out… to replace it with a slightly bigger hose to fit the Groco strainer side and a insert a sleeve to fill in the expected gap on the water pump side. I did use new stronger T-bar clamps to replace the old, used hose clamps that I’d removed.

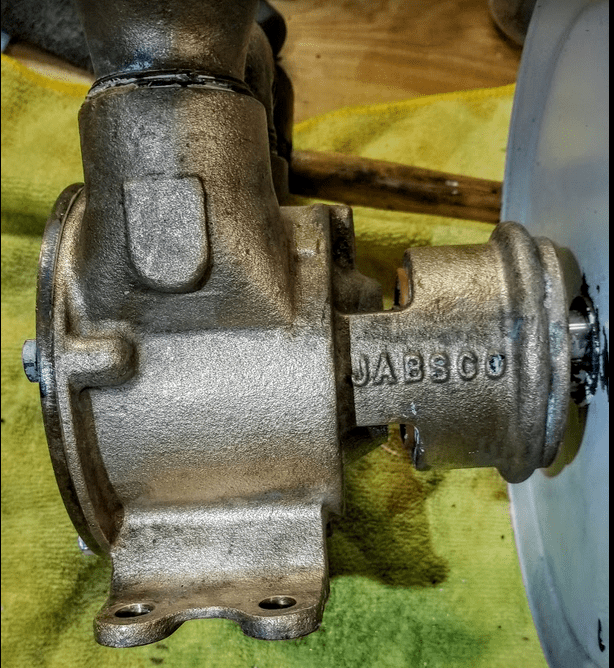

Last steps: Reassembly and test. All is fine mechanically. No leaks and the new impeller is moving plenty of water. Final act of this little skit: , clean up, fresh water wash of areas wetted with salt water during pump removal, touch up paint where needed, final clean up. Test under power.

The next to final view…

Next up… the oil change…

…Blair

Sometime back found an old spare jabsco water pump for the boat and cleaned it all up and polished and was on my list to deliver to Port Townsend on my trip up. Well 2000 degree fire I saw it on the floor with the melted aluminum from the machine tools. I burst into a tear. You aren’t getting it now.

Sent from my iPad

>

LikeLike

Bummer all around. Gotta tell ya… that port side impeller was not a walk in the park.

LikeLike

Your back must be doing considerably better if you can do all this. I’d have had trouble getting back up. But, good job!

LikeLike

PT baby!

LikeLike

It is better per se… walked 3 miles a couple of days ago. The gymnastics of impeller replacement are a strain, but with care and a new stiffer back brace I’ve made it mostly through. Compared to last October my back is 85% better. Can’t really expect much more than that, but for now… I will most likely be able to stand up to the riggors of cruising. We’re taking off in a week or so for a quick 3 day boat test. Then… off the the San Juans for a week…. then off into Canada for at least a month or… much more. Then the thought is to return to Port Ludlow. Regroup and then take off up North to the Broughton Archipelago for a look see then… we’re just not sure. Doesn’t matter really. We have lots of fuel, and water and food is available most places…

LikeLike

Bravo! I hate that job. As a friend always reminds me: it is never easy!

But it is rewarding

LikeLike

Stbd was easy… Port was another story. Had to remove entirely from engine including bracket it bolts to. Then The 1/5 inch hose fit the pump just fine, but would not get even close to fitting the Groco strainer. So I bought a 15/8 hose to install. We’ll see how that goes. It will be loose on the pump side but that’s pretty easy to shim. Yeesh!!

LikeLike

You are truly amazing! Sent from my Verizon, Samsung Galaxy smartphone

LikeLike